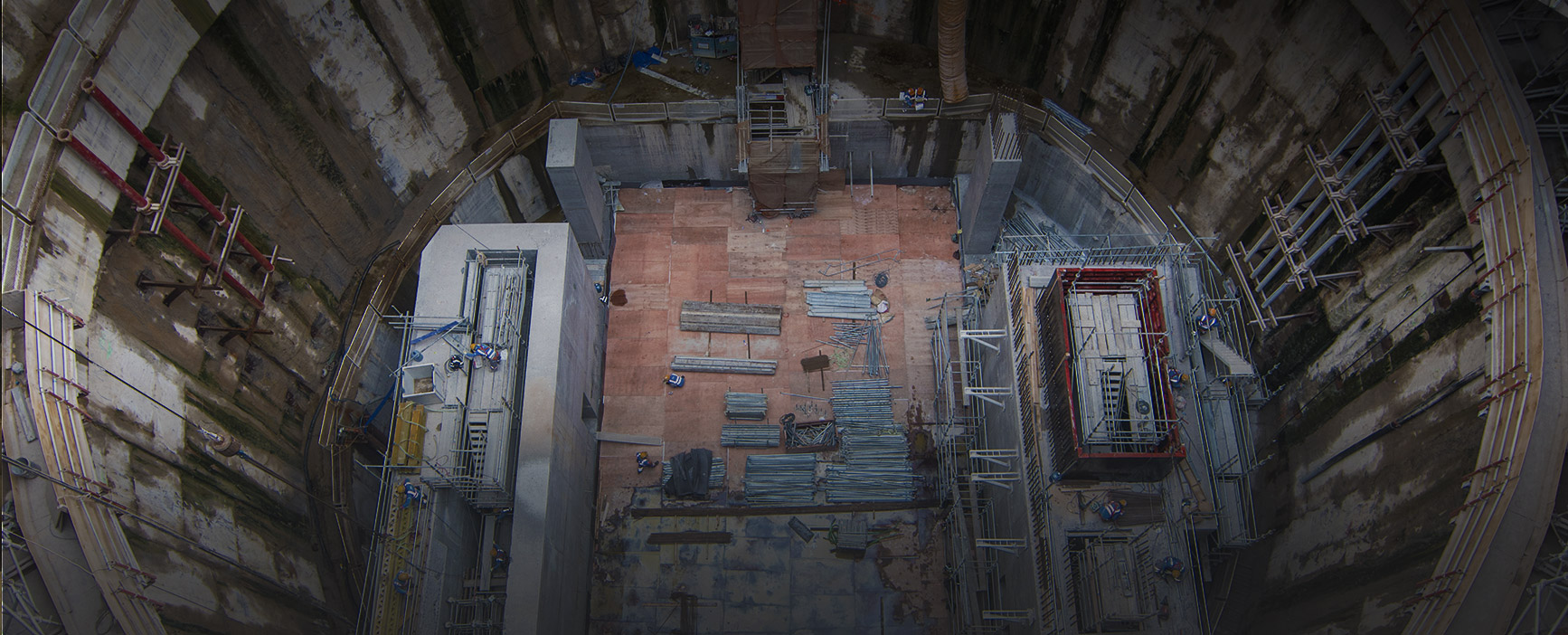

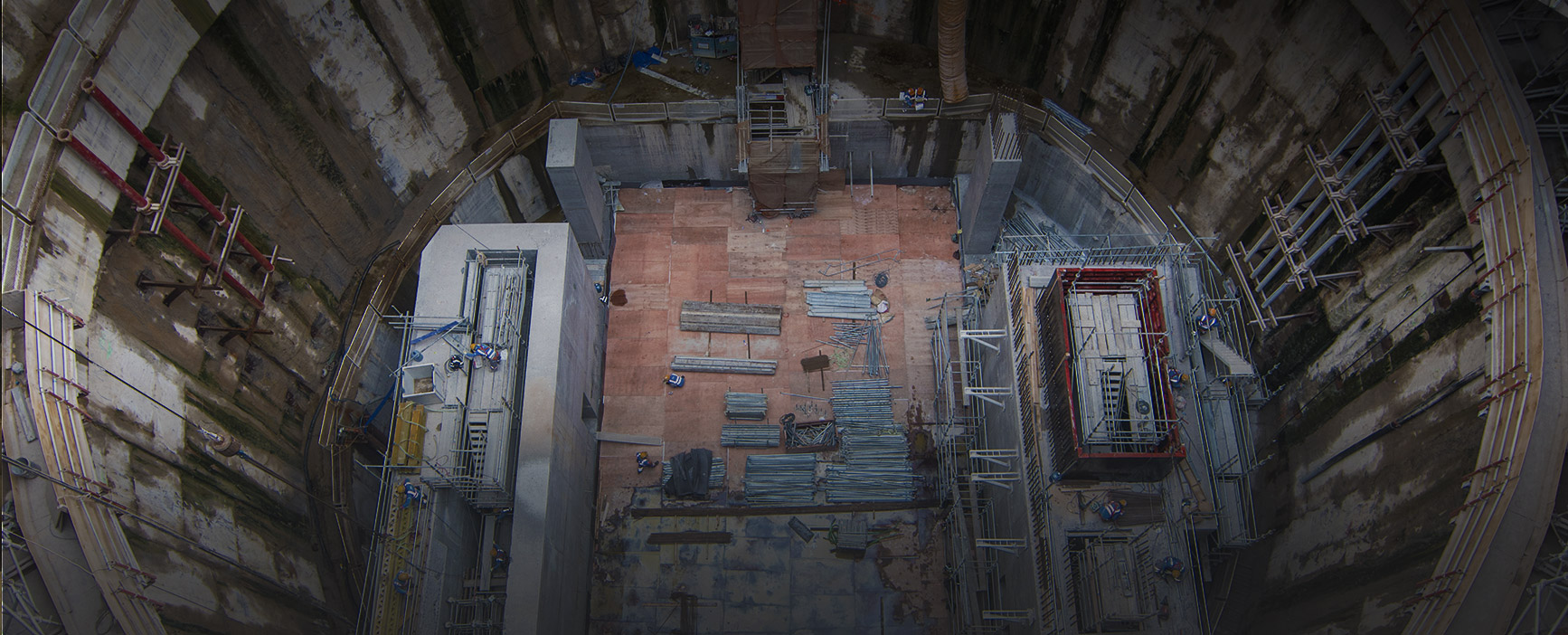

Deep Shafts - Tunnels

Being able to build down to 120 meters in depth

Deep shafts are critical access points for underground construction, providing vertical entry for tunnel boring machines (TBMs), utilities, ventilation systems, and emergency egress. Constructing these shafts in urban or geologically complex environments demands precise engineering, specialized methods, and robust retaining structures. VSL designs and builds deep shafts using diaphragm walls, CSM, and barrette techniques tailored to site constraints and shaft depth.

The role of Deep Shafts in underground infrastructure

Shafts serve as assembly points and access chambers for Tunnel Boring Machines.

Used for ventilation, utilities, or personnel entry in deep underground works.

Shafts allow vertical construction in high-density areas with minimal surface disruption.

Shafts often form part of the permanent waterproofing system and require precise cut-off solutions.

VSL’s Deep Shaft solutions

VSL delivers advanced deep shaft solutions that combine robust retaining systems, watertight construction, and specialized equipment to support complex underground works.

Shaft construction methods

• Diaphragm walls: Up to 120 m deep, constructed with verticality-controlled grabs or trench cutters.

• Circular and multi-cell shafts: Self-supporting structures that minimize or eliminate the need for internal strutting.

• Cutter Soil Mixing (CSM): Used for temporary support in non-load-bearing applications.

• Barrettes and secant piles: For restricted sites or irregular geometries.

Watertight and Strut-Free designs

Equipment and Depth Capabilities

• Low-headroom trench cutters for shafts in urban zones (as low as 5.3 m clearance)

• Excavation to depths exceeding 90 m

• Real-time verticality monitoring systems for wall construction

• Slurry treatment plants for diaphragm wall and CSM applications

Why Choose VSL for Deep Shaft solutions?

Turnkey expertise

From design to execution, VSL handles every stage including geotechnical analysis, wall construction, excavation, and verification testing.Urban and constrained site experience

Specialists in low-clearance, high-depth environments.High-performance designs

Shaft designs tailored to accommodate TBM logistics, groundwater control, and structural integration.Proprietary equipment

Custom-designed trench cutters and rigs for precision execution in varied geological conditions.

FAQs about Deep Shafts

VSL has built shafts exceeding 90 m in depth, with equipment capable of reaching depths up to 120 m.

Multi-cell shafts use circular or cellular diaphragm walls that are self-supporting, ideal for minimizing ground movement and maximizing usable space inside the shaft.

Yes. VSL uses short-boom rigs and compact trench cutters to operate in areas with as little as 5.3 m of headroom.