Heavy lifting - Tunnels

Carrying out complex shifting operations with minimum impact

Heavy lifting operations in tunneling and underground infrastructure projects require precise control, high-capacity equipment, and engineered methodologies to handle large structural elements under restricted conditions. From the installation of tunnel segments and precast beams to lowering heavy machinery or shifting TBM components, VSL provides turnkey heavy lifting solutions tailored to the constraints of underground works.

The critical role of Heavy lifting in tunneling

Tunnel shafts and underground chambers require lifting systems capable of operating in confined vertical and horizontal spaces.

TBMs, precast segments, and tunnel linings involve weights exceeding hundreds of tons, often requiring synchronized multi-point lifting systems.

Lifting operations in tunnels must meet strict tolerances for alignment and clearance while minimizing risks to surrounding structures and systems.

VSL’s Heavy Lifting services for tunnels

VSL delivers specialized heavy lifting solutions designed for the unique constraints of tunnel construction, ensuring safe, precise, and controlled handling of massive components in confined underground environments.

Lifting and lowering of tunnel segments

Solutions include:

• Custom-built lifting frames

• Temporary support and guidance systems

• Use of strand jacks or hydraulic jacks for incremental lowering

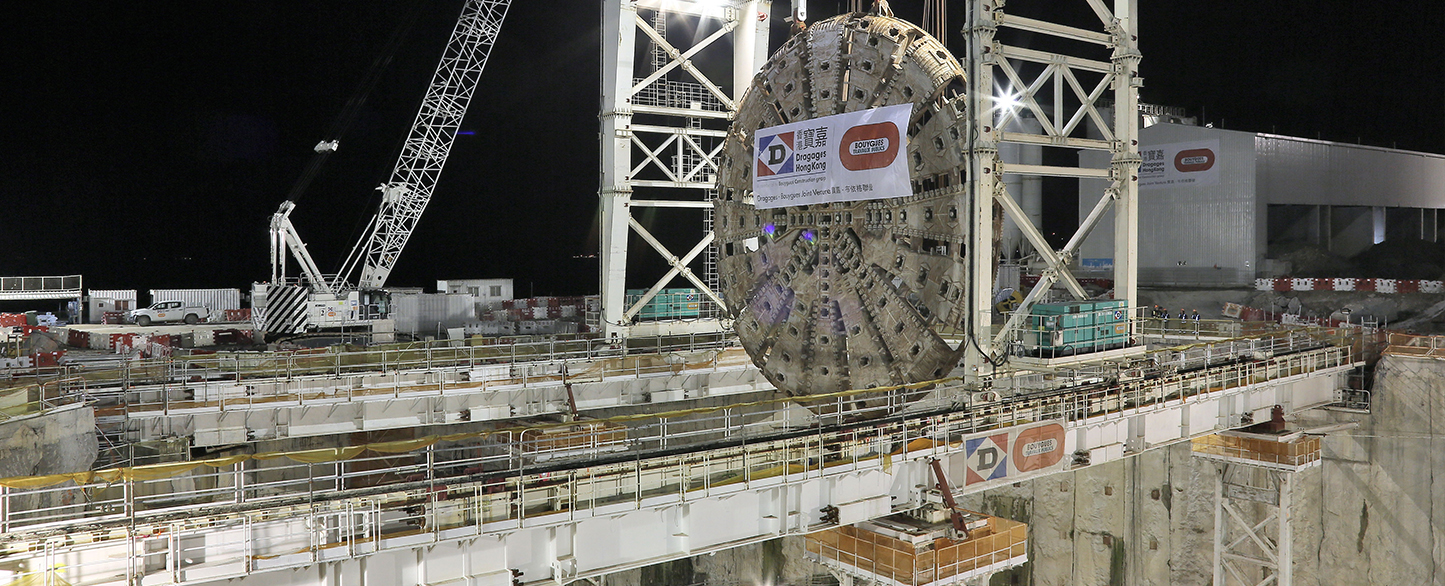

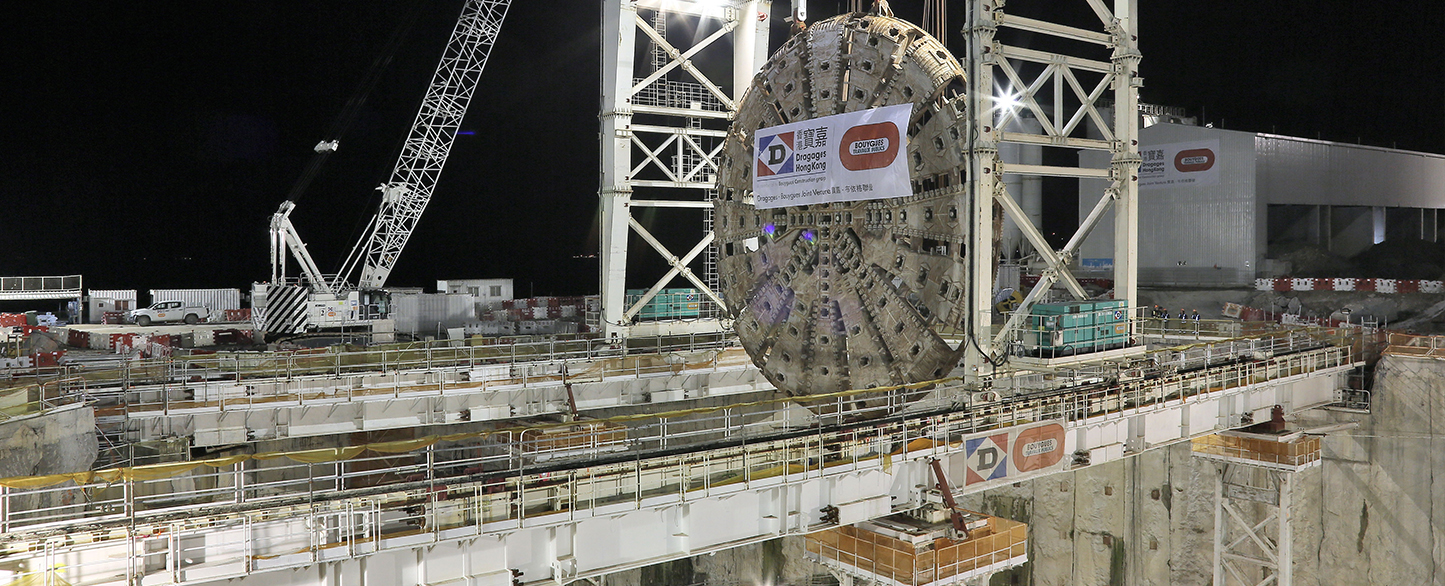

Positioning of TBM components

• Lowering TBM shields, cutterheads, or backup gantries

• Precise alignment for jacking pits and launch chambers

• Retrieval and disassembly of TBM components in tight spaces

Hydraulic strand jacking and synchronous lifting

Applications include:

• Multi-point lifts for balanced load distribution

• Limited-clearance shaft lowering

• Temporary supports for complex installation sequences

Why Choose VSL for heavy lifting?

Specialist in confined-space lifting

Solutions engineered specifically for vertical shafts and underground structures.Integrated delivery

Design, equipment, and execution provided in-house, ensuring full control of interface conditions.Global experience

Heavy lifting systems deployed on metro, water, and road tunnel projects worldwide.Proprietary systems

VSL’s strand jacking equipment supports synchronized operations and real-time load monitoring.

FAQs about Heavy lifting

VSL’s strand jack systems range from 30 to over 500 tons per jack and can be combined in multi-point configurations depending on load and geometry.

Yes. VSL has engineered lifting systems specifically for shafts with vertical access constraints and limited working height.

VSL uses synchronized control systems that monitor displacement and load at each lifting point, ensuring uniform motion and accurate positioning.