VSL dampers for stay cables

VSL’s damping systems protect stay cables from wind- and traffic-induced vibrations, increasing the durability and reliability of cable-stayed structures. The VSL Friction Damper and VSL VE Damper are engineered to mitigate all major vibration modes and are compatible with both new and existing bridges.

Why use cable dampers?

Stay cables are subject to dynamic phenomena: rain-wind vibration, vortex shedding, wake galloping, parametric excitation.

If uncontrolled, vibrations may cause excessive cable movement, user discomfort, or long-term fatigue of structural elements.

VSL offers:

- Project-specific vibration analysis

- Full integration into the VSL SSI 2000 system

- Retrofit solutions for strand or parallel wire cables

Key features

| Feature | VSL Friction Damper | VSL VE Damper | VSL H Damper |

|---|---|---|---|

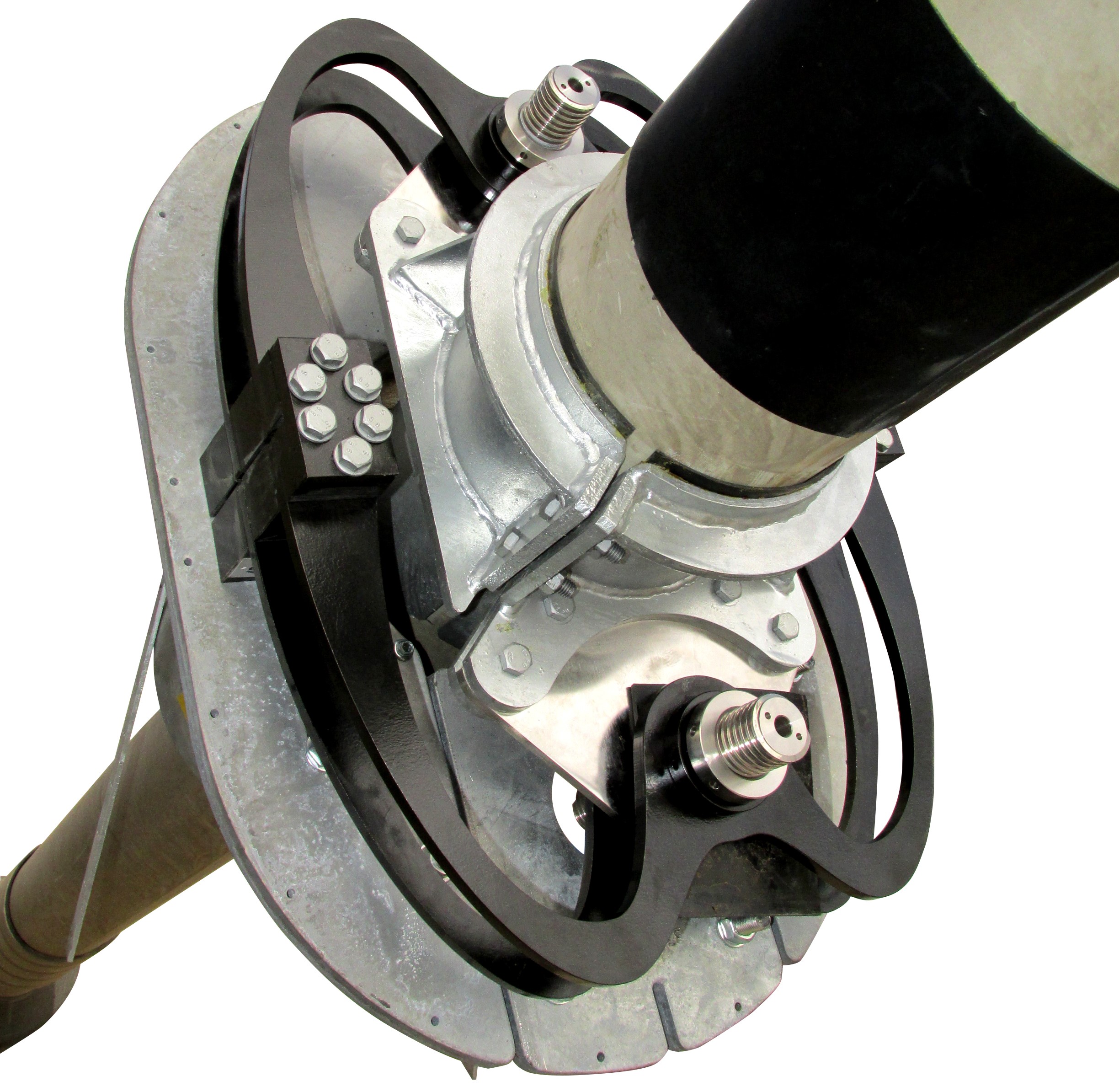

| Energy dissipation | Sliding friction interface (disc and pad system) | Shear deformation of high-damping rubber (HDR) pads | Viscous dampening as classical industry solutions |

| Best suited for | Long cables, high-amplitude or critical modes | Short to medium cables, confined or inaccessible locations | Specific client needs |

| Response to excitation | Activated above a threshold to avoid overuse, active as a guiding device otherwise | Always active, even under low amplitudes | Presents a striction, however, remains always loaded even under low amplitudes |

| Temperature sensitivity | Low – stable friction characteristics | None – viscoelastic performance is temperature-independent | None – hydraulic damper performance is temperature-independent |

| Adjustability | Adjustable friction force post-installation | Modular design (number/type of HDR pads) | No performance adjustment, viscous forces tuned during damper manufacturing |

| Installation | Internal or external configuration possible | Internal or external configuration possible | Internal or external configuration possible |

| Maintenance | Very low – wear-resistant materials, easily replaceable | Minimal – tested for 10M cycles and ≥60-year service life | Regular inspection required. |

| Visual impact | Minimum, installed inside a cylindrical casing with no protrusion | Same – identical outer geometry to Friction Damper | installed inside a cylindrical casing with no protrusion |

VSL also provides Hydraulic dampers on demand, featuring cables with an inhouse arrangement maintaining the cable cylindrical profile.

End-to-end services

VSL supports all phases of cable damping:

- Vibration risk assessment with advanced modelling tools

- Damper selection/design based on site-specific x/L ratio

- Fabrication, testing, supply of dampers/interfaces

- Installation, fine-tuning, commissioning during/after construction

- Retrofitting for bridges with unexpected vibration issues

Key benefits

- Aging-tested for 20 years functioning

- Fine-tuning on site without dismantling

- Integrated protective collar and neoprene ring shielding main cable elements

- Compatible with all cable geometries (PSS or PWS systems)

- Aesthetic integration with uniform outer appearance, mixable across bridge

- VSL Friction and VE dampers: minimal maintenance and full inspectability with modular components serviced with standard tools

- VSL Friction Dampers exceed 100% theoretical damping ratio for first cable vibration mode—ensuring structural safety and user comfort

FAQ about dampers for cable-stayed bridges

Yes. all damper types share the same visual profile and can be installed selectively by location or cable type.

Friction Dampers are threshold-activated (no dissipation under small cable movements), while VE Dampers or H dampers are continuously active.

Near the deck anchorage for optimum efficiency and accessibility. The distance between the damper and the nearest anchorage impacts the damping performance (which is proportional to the ratio x/L).

VSL Dampers are fully compatible with the VSL SSI 2000 system and can be installed inside the anti-vandalism pipe or externally.

Yes. VSL dampers meet international guidelines and are validated by laboratory and full-scale testing.