VSoL® retained earth walls

Mechanically stabilized earth (MSE) walls are widely used to retain embankments and support road and rail infrastructure.

The VSoL® retained-earth wall system combines customizable facing elements – precast concrete panels or steel mesh – with galvanized steel or polymeric reinforcements to deliver durable, modular, and cost-effective solutions, well suited to abutments, ramps, and constrained urban or mountainous environments.

Why choose VSOL®

VSoL® offers major advantages over traditional gravity and cantilever walls:

- Up to 60% material savings in concrete and steel

- Rapid installation with modular components

- Flexible design for poor soils, seismic zones, or aggressive environments

- Aesthetic freedom with a range of finishes and geometries

- Proven resilience under seismic and extreme load conditions

- Design life up to 120 years

Key features

Applications

VSoL® systems are used worldwide for:

- Bridge abutments

- Highway and railway retaining walls

- Industrial platforms and mining structures

- Sea walls, flood defenses, and protective barriers

- Temporary walls and construction platforms

- Green slopes and vegetated facings

Compatible with both public infrastructure and private developments, VSoL® adapts to all environments: mountainous, coastal, seismic, or urban.

Design and performance

A VSoL® wall forms a stable, reinforced earth block using three core elements:

- Concrete Facing Panels – retain the backfill and define the visual aspect

- Soil Reinforcement – mesh ladders or VStrips embedded in compacted fill

- Reinforced Fill – granular backfill providing interaction with reinforcements

These components combine to form a mechanically stabilized earth (MSE) wall, engineered to resist earth pressures and external forces.

Reinforcement options

| Steel Mesh Ladders | VStrips (Polymeric Reinforcement) |

|---|---|

| • Welded galvanized steel with high pull-out resistance • Superior interaction with compacted soil through transverse bars • Ideal for permanent or temporary structures | • Non-metallic strips made of polyester yarn in PE sheathing • Excellent durability in aggressive or marine environments Supplied in rolls (30–100 kN), easy to install, no corrosion risk • Innovative and patented connection to concrete facings |

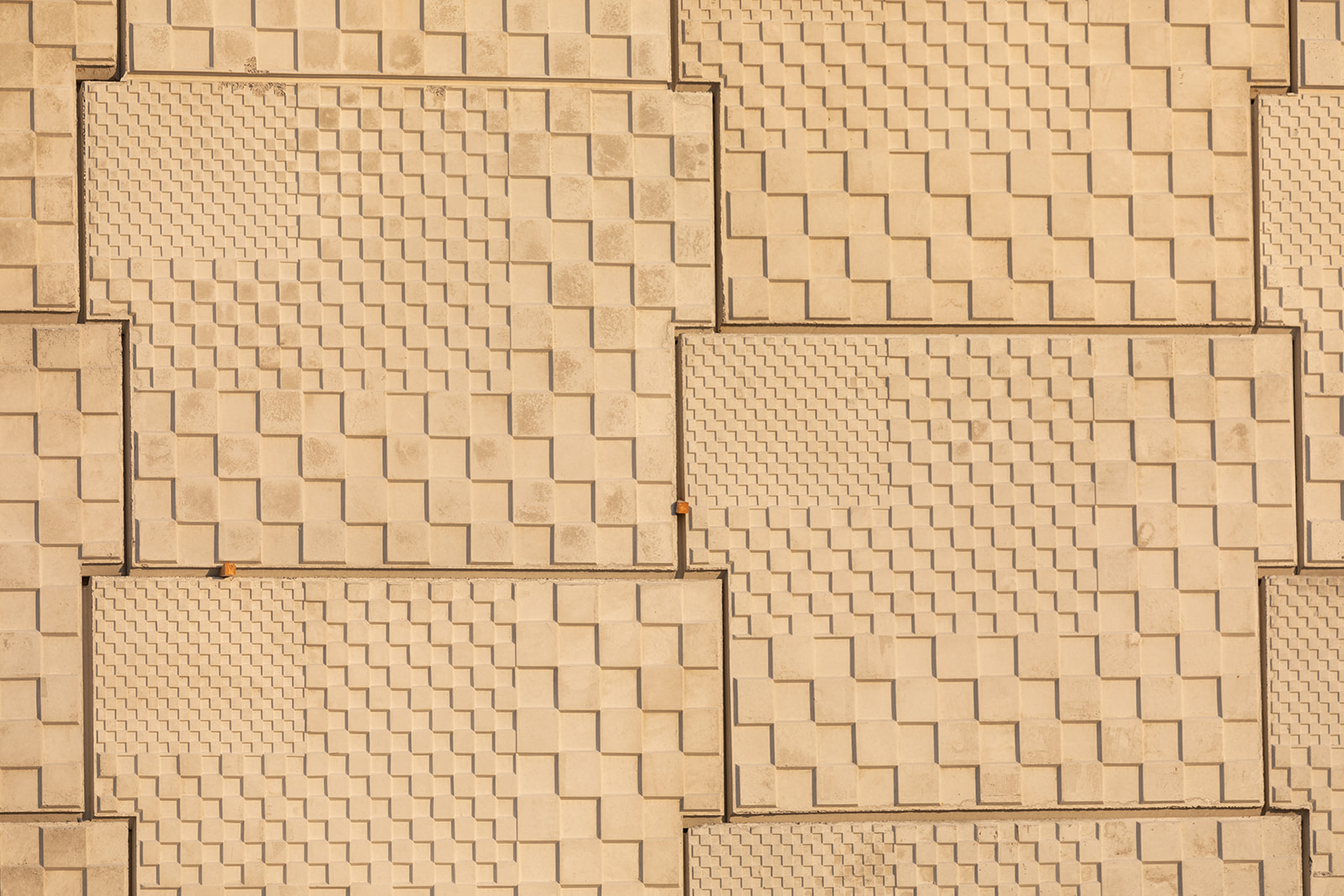

Facings and finishes

Available shapes include square, hexagonal, cruciform, and full-height (up to 14m).

| Facing Type | Description |

|---|---|

| Concrete panels | Standard square/rectangular (1.5–2.5m), textured or colored |

| Green facings | Geotextile + soil for vegetated walls |

| Wire mesh | Galvanized or black steel, fillable with rock or soil for natural appearance |

| Custom finishes | Stone relief, patterns, full-height artistic panels |

A low-carbon solution

VSoL® is part of VSL’s low-carbon portfolio. Key sustainability features include:

- Up to 60% lower CO₂ emissions compared to cast-in-place concrete walls

- Use of site-won fill reduces transport and material costs

- No deep foundations required in many cases

- Facings and fill materials are 100% recyclable

- Excellent landscape integration with green and artistic options

Example: On the Etihad Rail project, the combination of VSL-BEBO® arches and VSoL® walls reduced CO₂ emissions by 74% versus the original design.

End-to-end services

VSL provides turnkey services including:

- Feasibility studies and layout optimization

- Design (internal and external stability, settlement tolerance)

- Supply of reinforcements and precast facings

- Installation, backfilling, and compaction

- Monitoring of deformation, pressure, and settlement

- Maintenance and dismantling (for temporary applications)

Construction is generally carried out entirely from behind the wall — ideal for confined sites or uninterrupted traffic.

Key benefits

- Economical: Up to 50% cost savings vs. conventional walls

- Rapid: Built quickly with small crew and compact equipment

- Adaptable: Curved, stepped, or tiered designs possible

- Resilient: Performs under seismic events and poor soils

- Durable: Tested components, strict quality control

- Removable: Temporary walls dismantled and reused

Contact our experts

FAQ about VSoL

Yes. Its flexibility and soil–reinforcement interaction provide excellent seismic performance.

Yes. VSoL® is compatible with a wide range of site-won fills if they meet gradation and compaction criteria.

All designs comply with major international codes (EC7, BS 8006, AASHTO, GEO, etc.). Components are extensively tested.

Up to 120 years depending on the chosen reinforcement and environmental conditions.

Yes. It is ideal for platforms, access ramps, and site grading, and all components are recoverable.